Sunlight Illumination

Sunlight Illumination

Self-powered Ergonomic Lighting

Illumination in the buildings is energy-consuming. In 2015, 404 billion kWh electricity was consumed for lighting in the US. Saving energy, as well as creating enjoyable living experience, are our priorities.

I designed and developed a sunlight illumination system that traces and transfers sunlight for illumination purpose using lens, solar cells, stepper motors, optical fibers, and Arduino. The system achieved zero energy consumption with improved control mechanism and mechanical structure. This project won the first prize of Tsinghua Technology Contest (1%).

My Role:

Researcher & Engineer

Scope:

Literature Review, Mechanical Design, Programming, Testing & Iterating

Background

The growing fuel energy consumption has made our home planet suffer. To support continuous development and to reduce pollution, we need green energy. A simple idea came to my mind, that is, changing the way we use energy for illuminating. Therefore, I believe using solar energy for lighting directly may contribute to this dilemma.

This Natural Light Illumination System (NLIS) should utilize solar energy directly without transferring it to electricity energy. To achieve this, NLIS should trace the sun during daytime, and then lead the light indoor.

Mechanisms

I examined the basic principles of driving NLIS, and found the corresponding devices or parts.

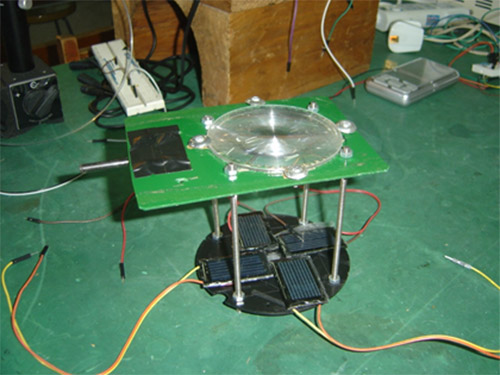

Optical elements:

Optical elements are for the purpose of gathering and transferring sunlight. These elements should be light, large, and have reasonable price. I used Fresnel Lens instead of glass lens eventually. The radius is 80mm and focus is 70mm and light transmission rate is 0.92. Also, plastic optical fibers were used. I used five parallel fibers in the prototype to gain intense light at the end.

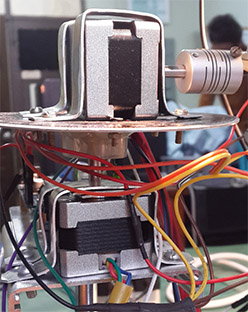

Motor Drivers:

Mechanical design is crucial for this NLIS system. The motor should be slow but accurate. Also, the motor should have relative high torque to drive the structure as well as lock the system. The system should be firmly stable when it stops. Servo might be a good choice since it is easy to control, however, I believed stepper motor is more suitable in terms of saving energy and accurate discrete motion.

To control both altitude angle and azimuth angle, we need at least two motors to control the motion on two axes. At north hemisphere, the motor should drive the optical part to rotate from east to west, and from low to high and low. I used two vertically-positioned motors eventually.

Control Mechanism

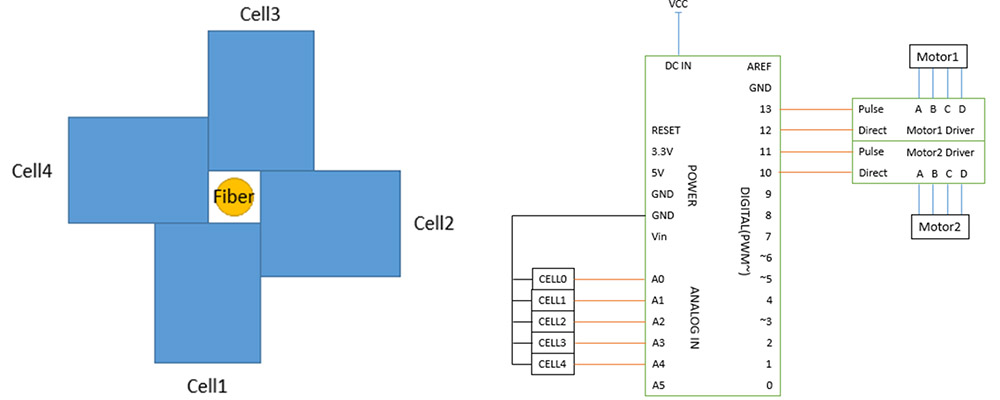

I used photosensitive elements to sensor the angle between lens and sun, and then they give a feedback for adjustment. In ideal circumstance, sunlight should go through the lens vertically at any time in order to achieve maximum efficiency. I realized that this angle changes slightly as time goes, but our feedback can be discrete. When sensing unequal light intensity (inequity in open-circuit voltage), the sensors control the NLIS to rotate to where light is the most intensive until reaching a new equilibrium again.

Arduino Uno is a popular single-chip microcomputer, and it can be programmed by C/C++. I used this to do the calculation.

Iterative Development

I kept modifying the structure of the system. The purposes of doing so are to reduce power consumption, to enhance overall stiffness, and to improve control accuracy.

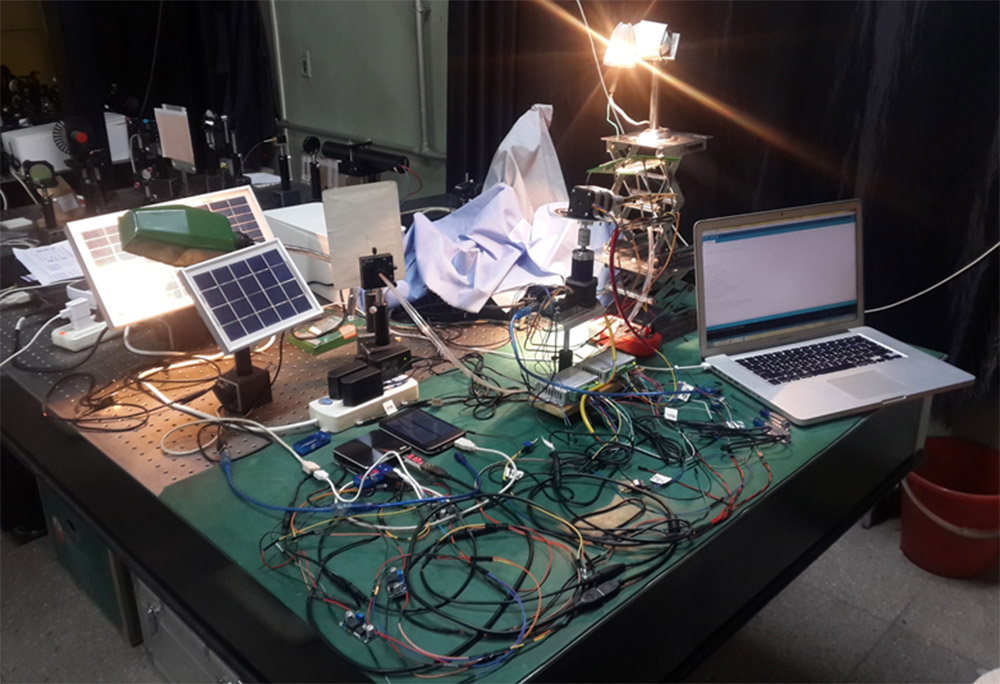

Iteration 1: Validating the Idea

I integrated the elements mentioned above to construct a basic NLIS prototype to examine if this principle worked. I used 5 photo-resistors to measure light intensity. These resistors were on the same plane of optical lens and covered with a black hollow cylinder with a small hole on it. Therefore, only one resistor would sense the light at a time.

The input pin of Arduino would detect the voltage change, and then generate an impulse to drive the stepper. Once the middle resistor sensed the most intensive light, the system is locked for 5 minute. The NLIS ran properly under this design.

Iteration 2: Improving Sampling Mechanism

The NLIS worked normally, but not perfectly. Sometimes the voltage on photo-resistor drifted, resulting in fluctuating voltage. What's more, sensors and lens were not homocentric, which means that the right position for sensors was not the right one for lens and fibers. I then replaced photo-resistors with solar cells. Four cells are placed evenly around the center (fibers). When the light spot moves, the cell will generate higher voltage, indicating a negative feedback.

Iteration 3: Modifying Mechanical Performance

As the system got heavier, stepper cannot effectively drive the NLIS, and vibrations started to adversely affect accuracy. I used gear box to slowed the rotations yet provided higher torque. Also, I reduced the protruding distance of the beam to diminish vibration. Also, by using solar cells and gear box, I significantly reduced energy consumption to 2 watts. If we added more solar cells, the system would operate without electricity.

Final Model

I eventually constructed a self-powered NLIS with steppers, single-chip microcomputer, solar cells, lens and fibers. The light intensity at the core was about 280 lux, which is definitely bright enough for reading. The system operated quietly with intangible vibration, providing a proper lighting environment for indoor workplace.